Feature:

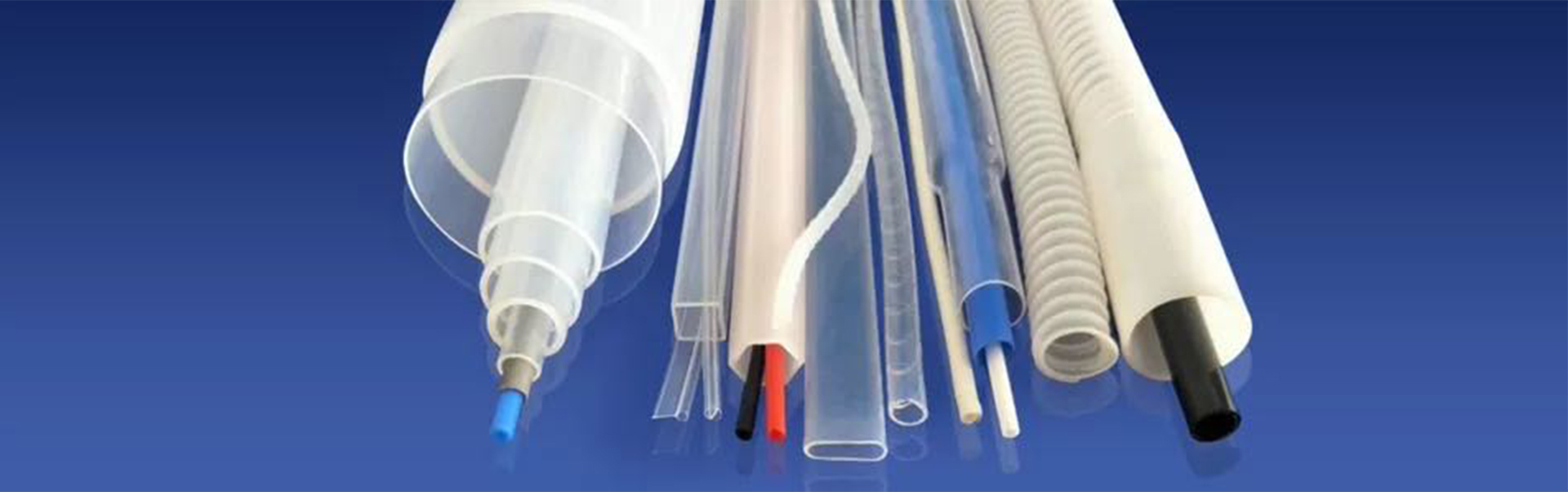

1,Appearance: transparent and smooth

2, physical and mechanical properties

| Indicator name | Unit | Index | |

| Density | g/cm3 | 2.12 | |

| Tensile Strength | MPa | Vertical and horizontal ≥15 | |

| Elongation at break | % | ≥250 | |

| Right angle tear strength | KN/m | ≥80 | |

| Volume resistivity | Ω·cm | ≥1×1017 | |

| Breakdown voltage strength | KV/mm | Thickness<0.05mm | >100 |

| 0.05<Thickness<0.1mm | >75 | ||

| thickness>0.1mm | >50 | ||

| proportion | PFA |

| density | 2.12-2.17 |

| Melting point (°C) | 302-310 |

| Maximum continuous use temperature (°C | 260 |

| Tensile strength (mpa) | 27-35 |

| Elongation rate (%) | 280-400 |

| Dielectric constant103HZ

106HZ |

2.1

2.1 |

| Volume resistivity(Ω-CM) | >1018 |

| Breakdown voltage strengthV/mil | 500 |

| Product features

PFA resists most chemicals, withstands a wide range of temperatures, and has a low-friction, nonstick surface PFA typically withstands a wider range of temperatures than FEP and ETFE Meets UL 94V0 specifications Color is translucent white |

Product description

The PFA round rod has a translucent white color and meets Underwriters Laboratories UL 94V0 specifications. PFA (perfluoroalkoxy) plastic resists most chemicals, withstands a wide range of temperatures, and has a low-friction surface that does not bond readily with other materials, giving it a nonstick characteristic. This material shares many of the same properties as PTFE and other fluoropolymers, but typically withstands higher temperatures than FEP and ETFE.

Plastic refers to a group of synthetic or semi-synthetic materials that have been engineered to achieve specific properties. The most notable characteristics of plastics are its low weight, machinability, corrosion resistance, and typically good thermal and electrical insulating properties. Certain plastic grades also offer optical transparency similar to glass, low-friction or self-lubricating surfaces, and exceptional impact resistance. Depending on their properties, certain plastic grades can be used as alternatives to metal, glass, and ceramic. Unlike metal, plastic may experience creep, which is deformation caused by longtime exposure to a constant load.

Tensile strength, used to indicate the material’s overall strength, is the peak stress it can withstand before it breaks. Corrosion resistance describes the material’s ability to prevent deterioration caused by atmosphere, moisture, or other medium. Wear resistance indicates the ability to prevent surface damage caused by contact with other surfaces. Toughness describes the material’s ability to absorb energy before breaking, while hardness (commonly measured as indentation hardness) describes its resistance to permanent surface deformation. Impact resistance is the measure of a material’s ability to absorb a shock of energy before breaking.

OPERATION

Welding is done by preheating the material with a hot air stream. The gun heats the air, but an air source must be provided by the gun. The welding rod is also preheated by the gun. When the materials are ready to be welded, the gun tip is simply run along the area where the weld is desired, feeding the welding rod manually in the process. The welding technique for PFA is similar to that used for polypropylene. However, the fusing temperature is much higher and added measures must be taken to ensure adequate ventilation.

Please contact Forbest if you have questions regarding welding PFA rod