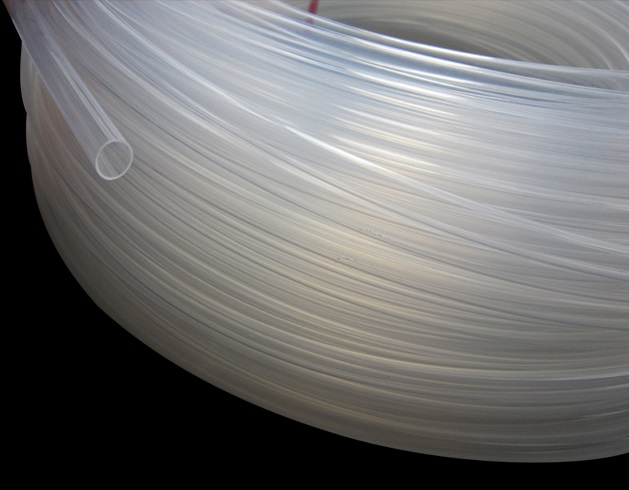

PFA Tubing Manufacturer

Forbest is a premier manufacturer of PFA Tubing, leveraging decades of expertise to deliver exceptional quality and performance. Our advanced production techniques ensure that our PFA Tubing meets the highest industry standards, making it ideal for applications across various sectors. Renowned for its superior chemical resistance, broad temperature tolerance, and non-stick properties, Forbest’s PFA Tubing is a reliable solution for demanding industrial environments.