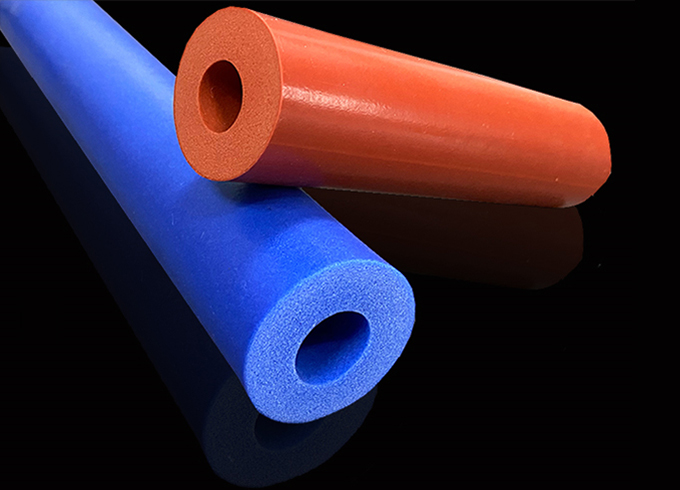

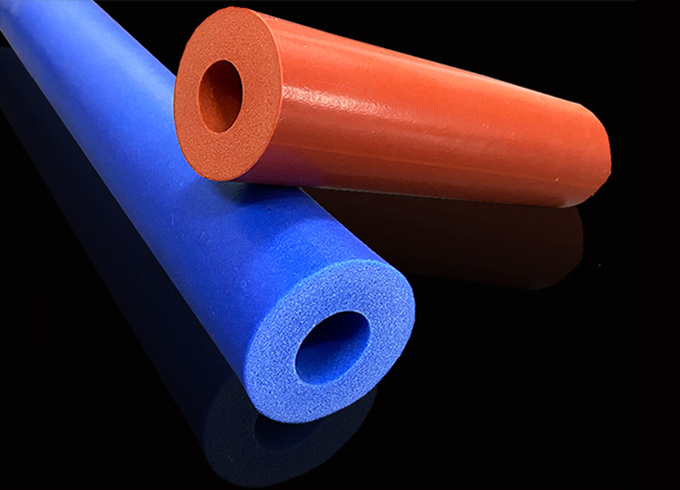

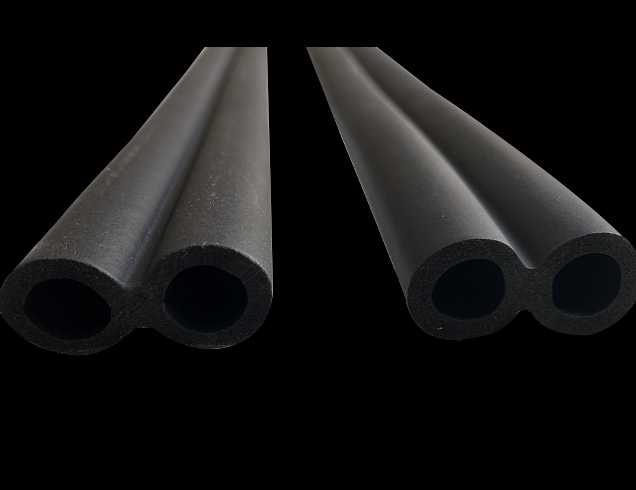

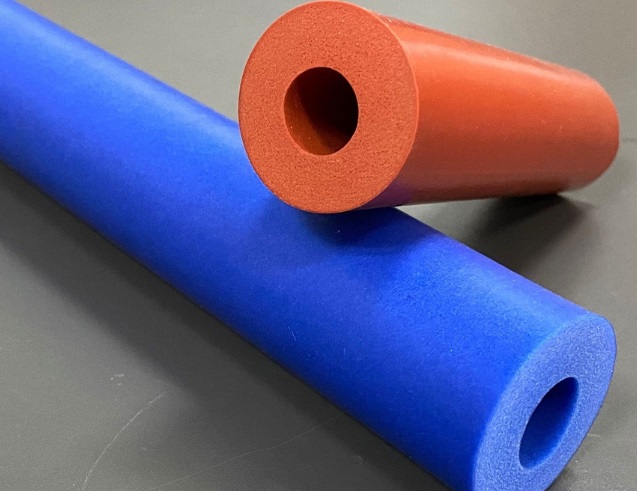

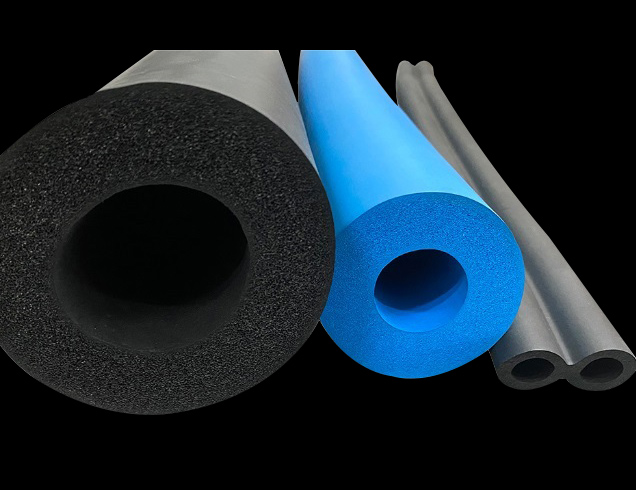

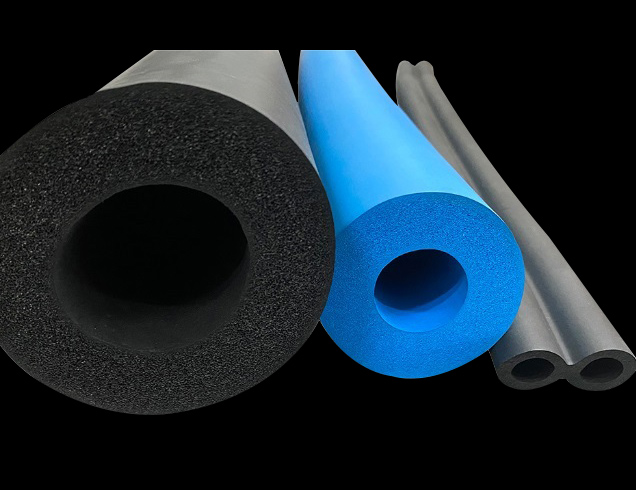

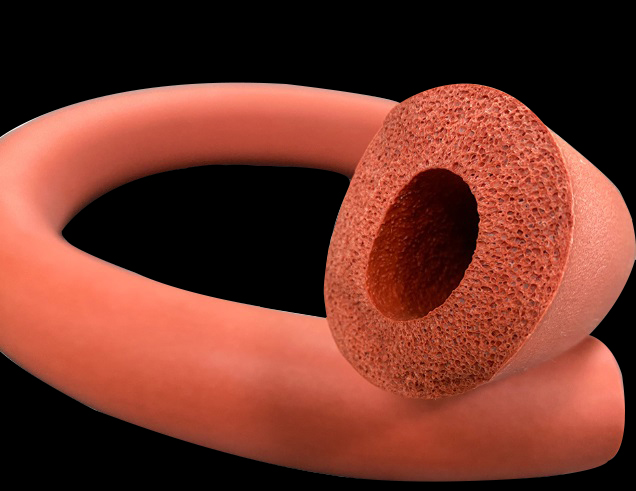

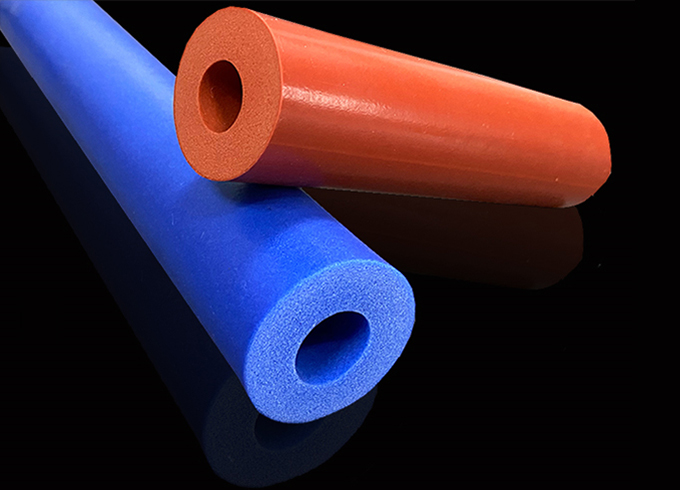

Made from a mix of silicone rubber and a cellular (sponge) construction, a Rubber Silicone Sponge Tube is a flexible, light tube. Excellent thermal insulating qualities, capacity to resist severe temperatures, and chemical and environmental factor resistance define this special material. Further advantages from the silicone rubber’s sponge construction include sound absorption, cushioning, and vibration dampening. Its adaptability makes it frequently utilised in many sectors, including automotive, construction, HVAC, and electronics, for uses including thermal insulation, sealing, and shielding sensitive components. Modern engineering solutions depend on the tube as its hollow character makes it easy to manipulate and tailored for certain demands.

Forbest’s Rubber Silicone Sponge Tube is a high-performance sealing and insulating solution, ideal for a wide range of industries, including baking, machinery manufacturing, electronics, and hot melt equipment. Our tubes are made from closed-cell silicone sponge foam, offering outstanding resistance to high and low temperatures (-40°C to +250°C), ozone, weathering, and UV radiation. They are compliant with ROHS, SGS standards, and meet FDA-grade requirements, ensuring quality and safety.

-

Compliance and Quality Assurance

Compliance and Quality AssurancePerfectly designed to satisfy strict compliance criteria is Best’s Rubber Silicone Sponge Tube. It is FDA Grade authorised and follows ROHS and SGS rules, so guaranteeing its safety for application in several sectors. This degree of compliance ensures that our product is free from dangerous ingredients and fit for uses in which quality and safety rule most importantly.

-

Flexible Mechanical and Temperature Attributes

Flexible Mechanical and Temperature AttributesOur silicone sponge tube is perfect for usage in surroundings with changing temperature conditions since it is made to resist extreme temperatures ranging from -40°C to +250°C. Its 250% elongation rate also gives great durability and flexibility. The tube’s density falls between 0.3 and 0.6 g/cm¹ and has a hardness between 7 and 20 Shore C, therefore providing a mix of softness and strength. Having a tensile strength of 10 psi, it can withstand considerable strain without sacrificing its integrity.

-

Application Flexibility and Customising

Application Flexibility and CustomisingForbest provides for our Rubber Silicone Sponge Tube unmatched customising choices. Any length and colour are possible, therefore it may be customised to fit your project’s particular needs. Its adaptability qualifies it for a broad spectrum of uses, including electronics, hot melt machinery, baking, and production of machinery. Our product can be tailored to meet your requirements whether your demands call for sealing, insulation, or as high-performance gaskets and seals.

-

Outstanding Durability and Performance

Outstanding Durability and PerformanceOur silicone sponge foam tube’s closed cell construction offers remarkable performance traits. Guaranturing long-lasting performance, it is quite resistant to harsh temperatures, ozone, and weathering. Excellent electrical characteristics, chemical stability, and radiation and ageing resistance are other properties of the tube. For uses demanding great performance and dependability, its good permeability and superior sealing qualities make it a sensible choice.

Forbest offers a high-quality Rubber Silicone Sponge Tube that is ROHS SGS compliant and meets FDA grade standards. This tube features a wide temperature range of -40°C to +250°C, 250% elongation, and a density of 0.3 to 0.6 g/cm³. Its hardness ranges from 7 to 20 Shore C, and it has a tensile strength of 10 psi. Available in any length and color, it is ideal for sealing, insulation, and creating high-performance gaskets and seals in industries such as baking, machinery manufacturing, electronics, and hot melt equipment.

The reason for choosing Forbest is our unremitting pursuit of excellent quality and performance of rubber silicone sponge tubes. Our products meet ROHS SGS standards and FDA grades, ensuring safety and reliability in various applications. The wide temperature range of -40°C to +250°C enables it to adapt to the use needs under extreme conditions. In addition, our products can be customized in length and color according to customer needs. They are widely used in the baking industry, machinery manufacturing, electronics industry and hot melt equipment, providing ideal solutions for sealing, insulation and high-performance gaskets and seals. Choosing Forbest means choosing the perfect combination of innovation, quality and safety.

-

Customer demand analysis

In the early stage of design, Forbest communicates and consults with customers in detail to deeply understand the specific needs and usage environment of customers. At this stage, we will ask about the application scenarios, functional requirements and usage conditions of the product to ensure that every detail can meet the actual needs of customers.

In the early stage of design, Forbest communicates and consults with customers in detail to deeply understand the specific needs and usage environment of customers. At this stage, we will ask about the application scenarios, functional requirements and usage conditions of the product to ensure that every detail can meet the actual needs of customers. -

Data conversion and design sketch

Based on the demand data provided by the customer, our design team converts it into operational design data. Designers start to make preliminary CAD sketches based on these data to ensure the rationality and feasibility of the design, and take into account future production costs and technical feasibility.

Based on the demand data provided by the customer, our design team converts it into operational design data. Designers start to make preliminary CAD sketches based on these data to ensure the rationality and feasibility of the design, and take into account future production costs and technical feasibility. -

Design review and adjustment

After the design sketch is completed, we will conduct an internal review and discuss the design details with relevant departments to ensure that each design meets the production requirements. In this process, the design team will make repeated adjustments based on the review opinions, optimize the design plan, and ensure that the final design can achieve the best performance and quality.

After the design sketch is completed, we will conduct an internal review and discuss the design details with relevant departments to ensure that each design meets the production requirements. In this process, the design team will make repeated adjustments based on the review opinions, optimize the design plan, and ensure that the final design can achieve the best performance and quality. -

Final plan confirmation

After many adjustments and optimizations, we will submit the final design plan to the customer for confirmation. Ensure that the customer has no doubts after reviewing all the design details, and enter the production preparation stage after confirmation. At this point, the design is fully in line with customer needs and is ready to start mass production.

After many adjustments and optimizations, we will submit the final design plan to the customer for confirmation. Ensure that the customer has no doubts after reviewing all the design details, and enter the production preparation stage after confirmation. At this point, the design is fully in line with customer needs and is ready to start mass production.

-

Pre-production preparation

Following confirmation of the design, Forbest will get ready for manufacture based on the last design drawings. This covers purchase of raw materials, line of production line preparation, and equipment commissioning in manufacturing. We make sure that every manufacturing condition is in place to guarantee seamless entry of the product into the production line.

Following confirmation of the design, Forbest will get ready for manufacture based on the last design drawings. This covers purchase of raw materials, line of production line preparation, and equipment commissioning in manufacturing. We make sure that every manufacturing condition is in place to guarantee seamless entry of the product into the production line. -

Production starts

Forbest's technical staff will function based on design drawings and quality criteria even after the production stage formally starts. Every manufacturing link is closely followed in line with the operational guidelines to guarantee that every rubber silicone sponge tube satisfies the design criteria and guarantees the homogeneity of production efficiency and quality.

Forbest's technical staff will function based on design drawings and quality criteria even after the production stage formally starts. Every manufacturing link is closely followed in line with the operational guidelines to guarantee that every rubber silicone sponge tube satisfies the design criteria and guarantees the homogeneity of production efficiency and quality. -

Control and quality check

Our quality control staff will do several checks throughout the manufacturing process to make sure every batch of rubber silicone sponge tubes satisfies FDA, SGS, and ROHS certifications. To guarantee that it can run stably and dependably in several application conditions, every product must go through thorough physical testing, temperature resistance testing and sealing testing.

Our quality control staff will do several checks throughout the manufacturing process to make sure every batch of rubber silicone sponge tubes satisfies FDA, SGS, and ROHS certifications. To guarantee that it can run stably and dependably in several application conditions, every product must go through thorough physical testing, temperature resistance testing and sealing testing. -

After-sales assistiveness and product delivery

Forbest will do a last quality check on every rubber silicone sponge tube once manufacturing is finished to guarantee that it is fault free. Following the inspection, the product will be timelyly packaged and delivered to the client. We also offer thorough after-sales service to guarantee that any issues consumers run across during operation can be quickly resolved.

Forbest will do a last quality check on every rubber silicone sponge tube once manufacturing is finished to guarantee that it is fault free. Following the inspection, the product will be timelyly packaged and delivered to the client. We also offer thorough after-sales service to guarantee that any issues consumers run across during operation can be quickly resolved.

-

Is silicone rubber a good thermal insulator?

Silicone is not that good of an insulator. It traps heat about as well as other plastics, but plastics are generally decent at trapping heat. It is pretty good at staying strong and not burning or melting at high temperatures, which is why you see it used for oven mitts and other kitchen items that get hot.

-

What is the temperature resistance of Rubber Silicone Sponge Tube?

Rubber Silicone Sponge Tube boasts excellent temperature resistance, maintaining its physical properties across a wide range of temperatures. Generally, this material can be used continuously from -70℃ to 260℃. For instance, certain types of silicone sponge tubes can withstand temperatures up to 250℃. This superior temperature resistance makes it ideal for industries with significant temperature fluctuations, such as aerospace, automotive, and electronics.

-

How is the sealing performance of Rubber Silicone Sponge Tube?

Rubber Silicone Sponge Tube has very good sealing performance, primarily due to its closed-cell structure design. The closed-cell structure means that each air pocket is completely sealed, preventing water, air, and other fluids from penetrating into the cells. As a result, this material performs exceptionally well in sealing applications, effectively preventing the leakage of liquids and gases. For example, in food processing equipment, silicone sponge rubber products are used as gaskets and seals to ensure that the equipment interior remains free from external contamination.

-

How is the chemical and weather resistance of Rubber Silicone Sponge Tube?

Rubber Silicone Sponge Tube has good chemical and weather resistance. It is resistant to many chemicals and is not easily corroded. Additionally, this material has excellent resistance to ultraviolet light and ozone. Due to its inorganic siloxane backbone structure, silicone materials can maintain long-term performance stability under ultraviolet radiation and ozone environments. This makes Rubber Silicone Sponge Tube suitable for outdoor use, capable of withstanding the erosion of sunlight, rainwater, and pollutants.

-

Is Rubber Silicone Sponge Tube suitable for use in food-grade applications?

Yes, Rubber Silicone Sponge Tube can be suitable for use in food-grade applications. It is made from food-grade silicone materials that are non-toxic and odorless. These materials do not react with food substances and do not produce harmful substances when in contact with food. Therefore, it can be used in food processing equipment, food packaging, and other food-related applications, ensuring the safety and hygiene of food products.