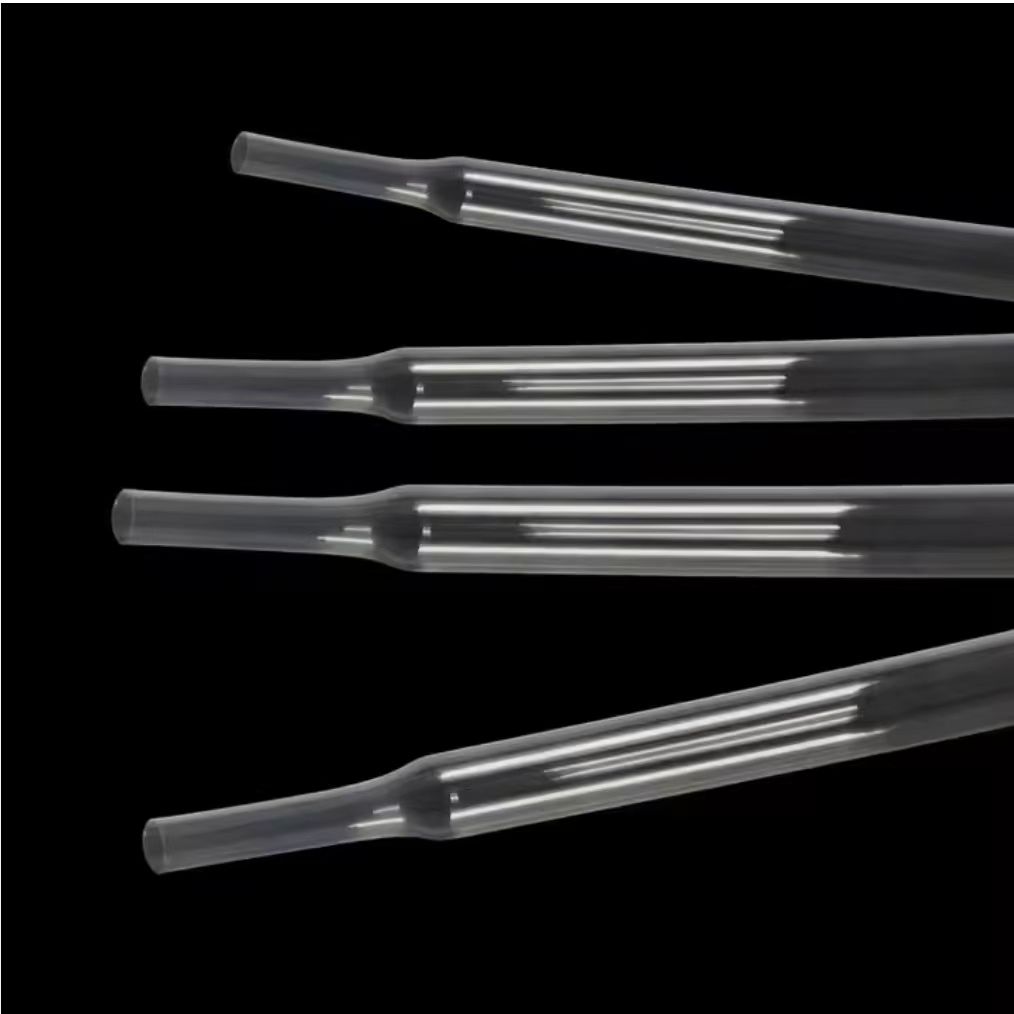

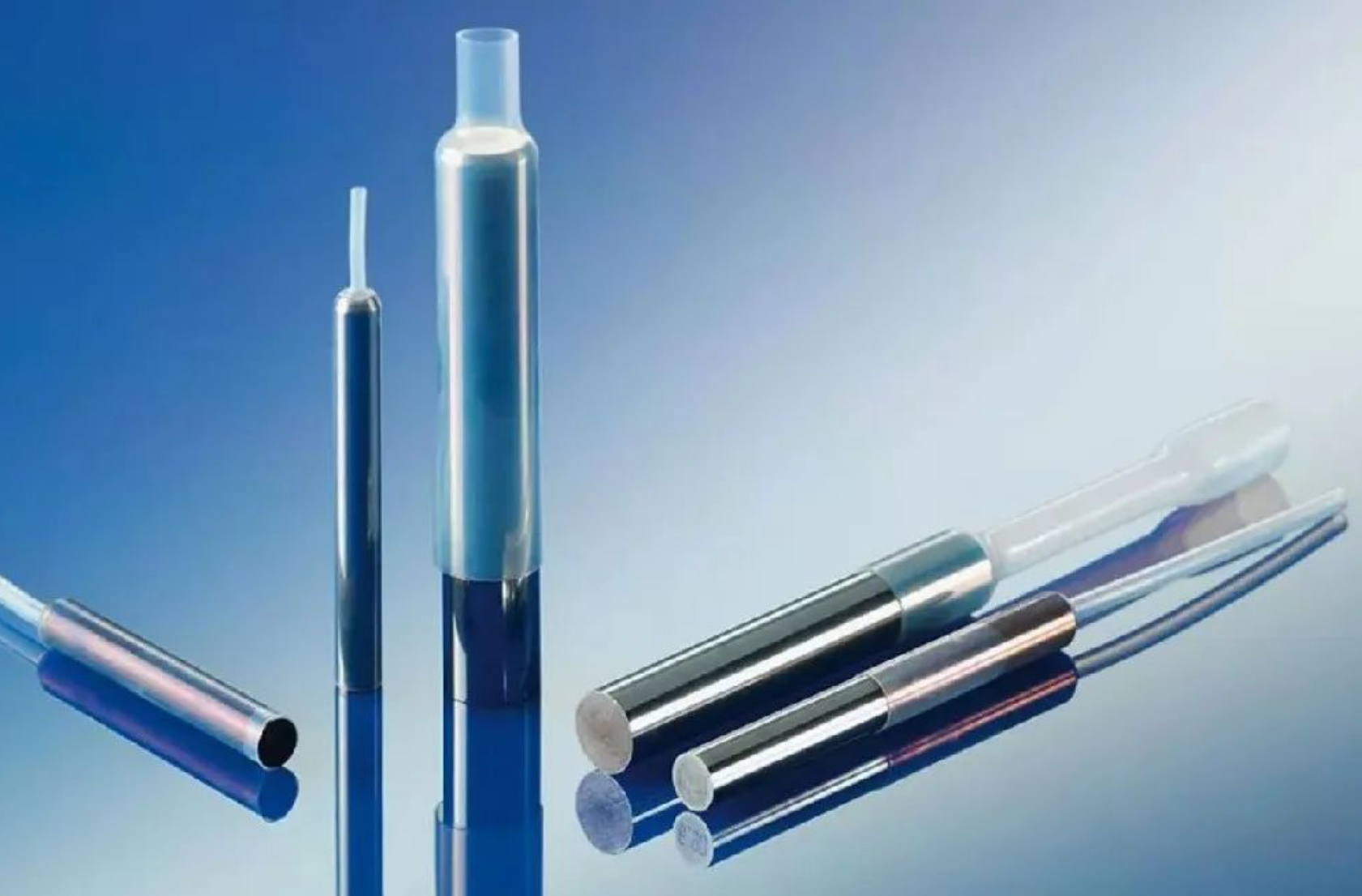

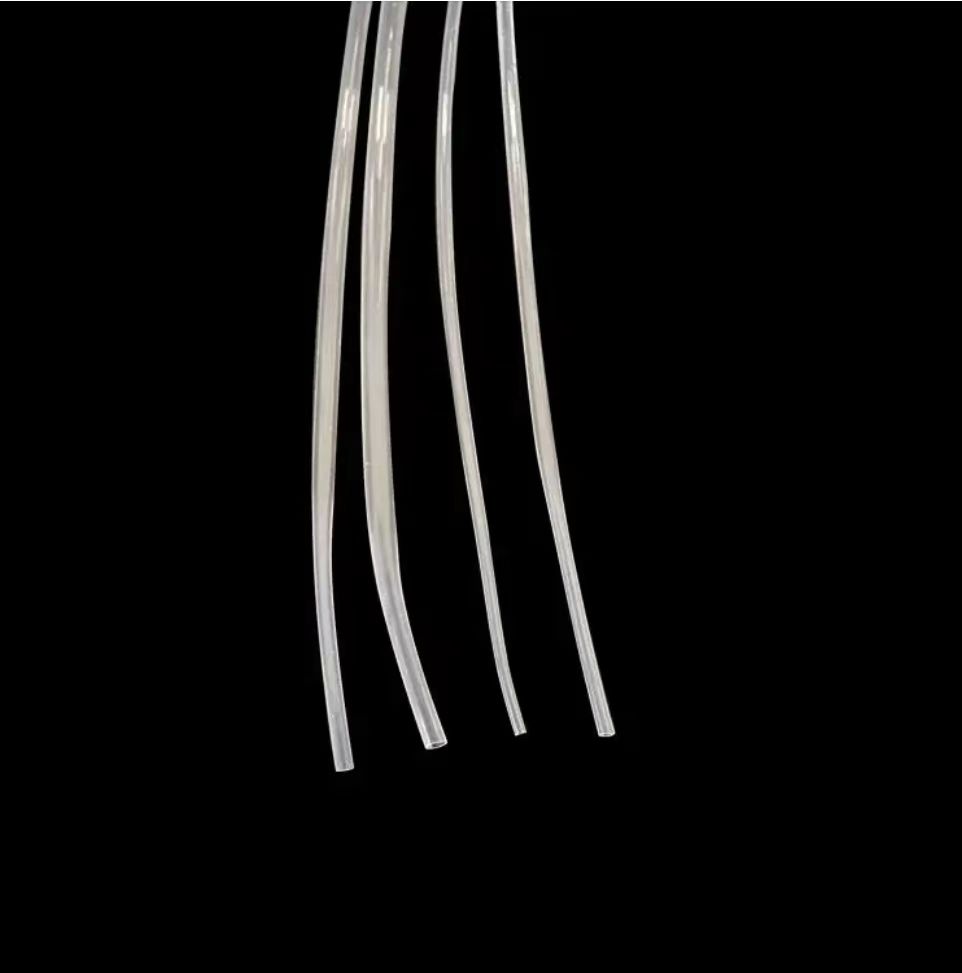

FEP Heat Shrink Tubing is a high-performance fluoropolymer material designed for a wide range of applications. It offers excellent chemical resistance, thermal stability, and electrical insulation properties. With a low shrink temperature and high transparency, it provides a secure, conformal fit over various shapes and sizes. Suitable for use in medical devices, electronics, and chemical processing, FEP tubing ensures reliable protection and insulation while maintaining flexibility and durability.

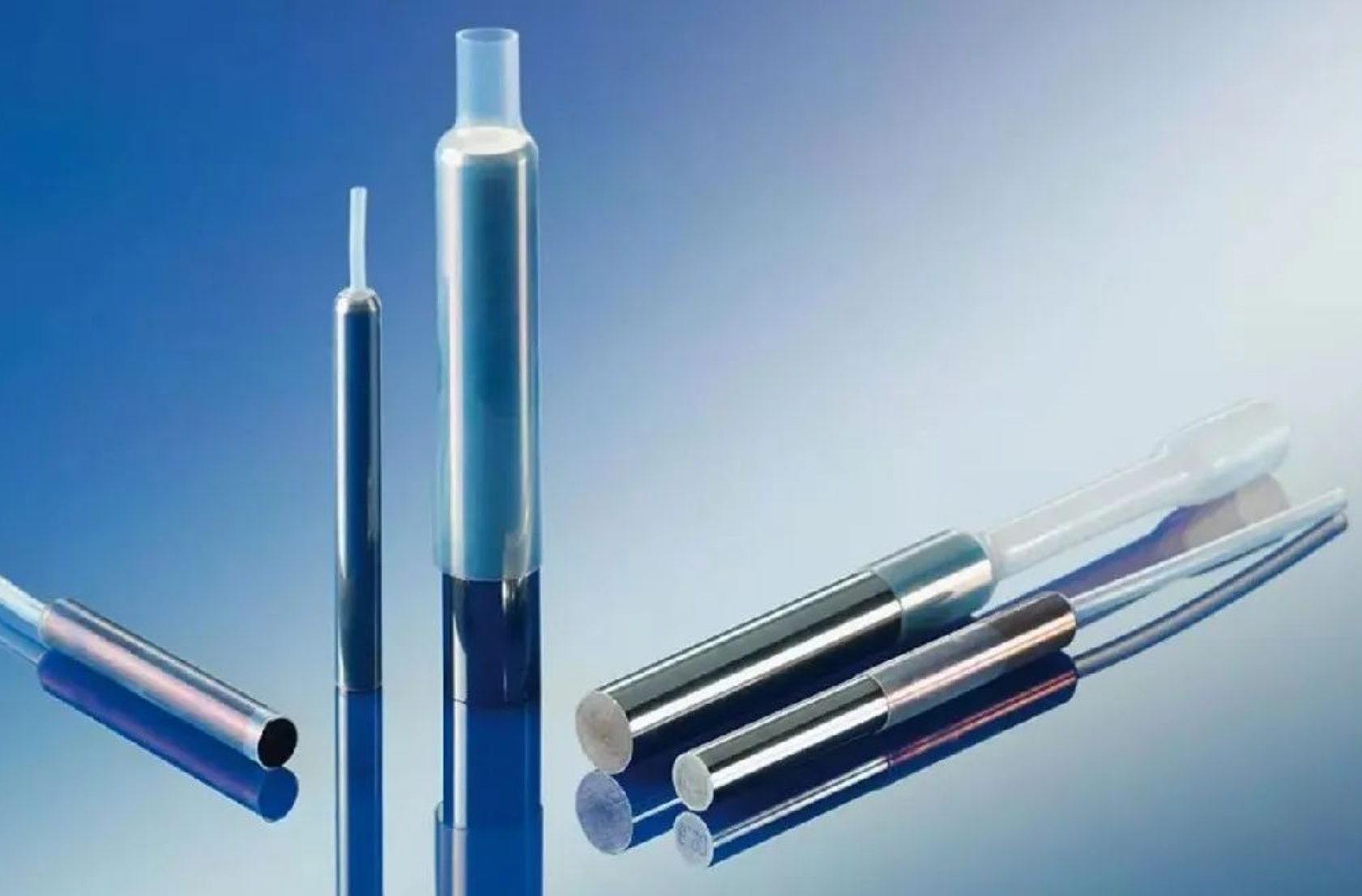

Forbest’s FEP Heat Shrink Tubing Series is designed to meet diverse industrial needs with its versatile and high-performance materials. This series features excellent temperature resistance, operating continuously up to 200°C and shrinking at around 210°C. Available in various sizes and shrink ratios, the series offers customizable solutions for applications ranging from medical device manufacturing to electrical insulation. Its biocompatibility, chemical inertness, and transparency make it ideal for medical applications, while its durability and UV resistance ensure long-term reliability. Whether used as a UV lamp cover or for protecting sensitive components, Forbest’s FEP Heat Shrink Tubing Series provides robust protection and performance.

-

Exceptional Heat Resistance and Chemical Stability

Exceptional Heat Resistance and Chemical StabilityForbest’s FEP heat shrink tubing maintains stability at temperatures up to 450°F (around 232°C), making it ideal for high-temperature sterilization and cleaning processes. FEP material also shows outstanding resistance to a variety of chemicals, including common disinfectants and solvents, ensuring its durability in medical equipment applications.

-

Low Shrink Temperature and High Transparency

Low Shrink Temperature and High TransparencyThe shrink temperature of FEP heat shrink tubing is typically around 210°C (410°F), ensuring that sensitive components are not damaged during installation. Additionally, FEP offers high transparency, making it particularly effective for applications that require visual inspection, such as catheter manufacturing and endoscopic equipment.

-

Excellent Lubricity and Low Friction Coefficient

Excellent Lubricity and Low Friction CoefficientThe surface of FEP heat shrink tubing provides excellent lubricity, reducing friction during operation, which enhances smooth performance and patient comfort. This low friction property is especially beneficial for use in interventional medical devices.

-

Customization Options and Silicone-Free Manufacturing

Customization Options and Silicone-Free ManufacturingForbest offers a variety of sizes and shrink ratios, with customization services available to meet specific needs. The shrink ratio can reach up to 1.8:1. Furthermore, Forbest’s FEP heat shrink tubing is made using a silicone-free manufacturing process, ensuring purity and biocompatibility while preventing potential contamination from silicone materials.

Forbest’s FEP heat shrink tubing has become the preferred material in medical device manufacturing due to its excellent heat resistance and chemical stability. It can work stably in high temperature environments and is resistant to a variety of chemicals, making it particularly suitable for use in high-temperature sterilization and cleaning processes. At the same time, FEP heat shrink tubing has high transparency, can provide clear visual inspection, and has good surface lubricity, which reduces friction and improves the smoothness of equipment operation. Forbest also provides customized services to help meet the needs of different medical devices and ensure the safety and reliability of the equipment.

Forbest’s FEP heat shrink tubing offers exceptional thermal and chemical resistance, low shrink temperature, and high transparency. With a silicone-free manufacturing process, it ensures purity and biocompatibility. Forbest provides a wide range of sizes and custom solutions to meet specific customer needs, ensuring reliable performance in various applications. Choose Forbest for high quality and a trusted partnership.

-

Demand Analysis

Communicate in depth with customers to understand their specific requirements for FEP heat shrink tubing, including size, shrink ratio, transparency and heat resistance.

Communicate in depth with customers to understand their specific requirements for FEP heat shrink tubing, including size, shrink ratio, transparency and heat resistance. -

Design Drawings

Use advanced CAD software to draw detailed heat shrink tubing design drawings to ensure that the product fully meets customer needs and can perform at its best in actual applications.

Use advanced CAD software to draw detailed heat shrink tubing design drawings to ensure that the product fully meets customer needs and can perform at its best in actual applications. -

Technical Communication

Detailed docking of design drawings and technical requirements with the production department to ensure that all design details are accurately understood and executed.

Detailed docking of design drawings and technical requirements with the production department to ensure that all design details are accurately understood and executed. -

Production Coordination

The production staff of FEP heat shrink tubing works closely with the technical team to ensure that each batch of products maintains high standards of quality control during the production process and makes necessary customized adjustments according to customer needs.

The production staff of FEP heat shrink tubing works closely with the technical team to ensure that each batch of products maintains high standards of quality control during the production process and makes necessary customized adjustments according to customer needs.

-

Raw material selection and preparation

We select high-quality FEP resins and strictly screen and inspect them to ensure that the raw materials meet customer needs and industry standards. After pre-treatment, FEP resin enters the production stage.

We select high-quality FEP resins and strictly screen and inspect them to ensure that the raw materials meet customer needs and industry standards. After pre-treatment, FEP resin enters the production stage. -

Extrusion and molding

FEP resin is processed into tubing through advanced extrusion technology to ensure the uniformity and consistency of its tubing. During this process, we closely monitor temperature, pressure and other key parameters to ensure the high-performance characteristics of the product.

FEP resin is processed into tubing through advanced extrusion technology to ensure the uniformity and consistency of its tubing. During this process, we closely monitor temperature, pressure and other key parameters to ensure the high-performance characteristics of the product. -

Heat shrinking

At this stage, the FEP tubing is processed through a precise heat shrinking process to achieve the desired shrink ratio and size. Our equipment ensures that each tube shrinks at the appropriate temperature to avoid heat damage and ensure dimensional accuracy.

At this stage, the FEP tubing is processed through a precise heat shrinking process to achieve the desired shrink ratio and size. Our equipment ensures that each tube shrinks at the appropriate temperature to avoid heat damage and ensure dimensional accuracy. -

Quality Inspection and Packaging

Each batch of FEP heat shrink tubing will undergo strict quality inspection, including tests on size, transparency, heat resistance and chemical stability. Only products that pass these rigorous tests will enter the final packaging stage to ensure that the products can be safely and reliably delivered to customers.

Each batch of FEP heat shrink tubing will undergo strict quality inspection, including tests on size, transparency, heat resistance and chemical stability. Only products that pass these rigorous tests will enter the final packaging stage to ensure that the products can be safely and reliably delivered to customers.

-

What is the service life of FEP heat shrink tubing?

FEP heat shrink tubing has a long service life, depending on the use environment and frequency. Under normal use conditions, its durability and stability enable it to maintain performance for a long time.

-

Does Forbest provide customized services for FEP heat shrink tubing?

Yes, Forbest provides customized services, including size, color, shrink ratio, etc. It can be customized according to the specific needs of customers.

-

How long is the delivery time for customized FEP heat shrink tubing?

The delivery time depends on the complexity of the customization and the order volume. Usually, the delivery time for standard customized services is 2-3 weeks.

-

Is Forbest's FEP heat shrink tubing quality guaranteed?

Yes, Forbest provides quality assurance.

-

How to buy Forbest's FEP heat shrink tubing?

You can learn about product details and place an order through Forbest's official website, or you can directly contact Forbest's sales team for quotes and support.