In the ever-evolving field of medical technology, materials used in device fabrication must meet exceptionally high standards for safety, durability, and performance. One such material that has become indispensable in the manufacture of medical devices is the Fep heat shrink tube. Made from fluorinated ethylene propylene (FEP), this specialized tubing offers unique advantages for applications requiring high biocompatibility, sterilization compatibility, and mechanical strength.

Also referred to in commercial contexts as EP Heat Shrink Tube or Medical FEP Heat Shrink Tube, this product provides a reliable solution for medical manufacturers seeking advanced insulation, protection, and visibility in their devices. Below, we explore the full spectrum of properties and applications that make Fep heat shrink tube a standout choice in modern healthcare engineering.

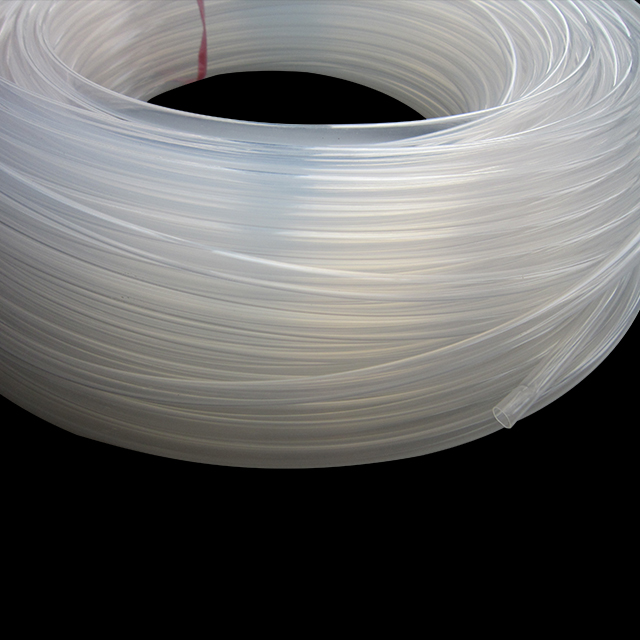

FEP Heat Shrink Tube

What is FEP and Why It Matters in Medicine

Fluorinated ethylene propylene, commonly known as FEP, is a thermoplastic polymer that shares many properties with PTFE (Teflon), yet offers improved transparency and flexibility. These characteristics are critical in medical environments where visibility, sterility, and resilience are required.

When fabricated into heat shrink tubing, FEP can contract around complex geometries by applying heat, forming a tight and secure seal. This makes the Fep heat shrink tube a versatile protective layer for wires, catheters, surgical instruments, and various implants.

We also offer custom-length cutting services to meet client-specific requirements, ensuring precise application and reduced waste in manufacturing.

Biocompatibility – Safe for Direct Contact with Human Tissue

One of the primary requirements for any material used in medical settings is biocompatibility. Fep heat shrink tube meets strict biocompatibility standards, meaning it will not trigger allergic reactions, immune responses, or other adverse effects when used in or around the human body. This makes it particularly suitable for medical components that come into prolonged contact with tissue or blood.

From catheters and implant delivery systems to diagnostic equipment, the Medical FEP Heat Shrink Tube is engineered to interact safely with the human body, ensuring peace of mind for healthcare professionals and patients alike.

Outstanding High-Temperature Resistance

Sterilization is a non-negotiable requirement in medical device manufacturing. The ability to withstand high temperatures without deformation or material breakdown is a key attribute of the Fep heat shrink tube. Whether exposed to steam, dry heat, or chemical sterilization techniques, FEP tubing retains its structural integrity.

FEP tubing features a high working temperature range, capable of maintaining stable performance in environments up to 200°C. This makes it compatible with a variety of sterilization methods—including autoclave (high-pressure steam), gamma radiation, ethylene oxide (ETO), and dry heat—offering broad flexibility for manufacturers who must comply with stringent hygiene protocols.

Optical Clarity for Visual Inspection

In many medical applications, especially those involving imaging or diagnostics, transparency is crucial. The Medical FEP Heat Shrink Tube is prized for its outstanding transparency, allowing healthcare professionals to perform visual inspections of internal components or fluids passing through the system.

Because of its high transparency, Fep heat shrink tube is commonly used in products like endoscopes, tubing systems, and optical sensor housings. It is also available in a range of custom colors to allow for system identification, coding, or aesthetic matching.

Excellent Electrical Insulation

Electrical safety is critical in the healthcare industry, especially in the design of electro-surgical instruments, diagnostic tools, and monitoring devices. Fep heat shrink tube provides excellent dielectric strength, making it a superior choice for insulating wires, leads, and connections within medical systems.

With its low dielectric constant and high breakdown voltage, FEP tubing prevents short circuits, ensures consistent device performance, and reduces the risk of accidental electrical exposure to patients or clinicians.

Mechanical Protection and Wear Resistance

In medical environments, devices are often subject to repeated use, sterilization, and mechanical manipulation. Therefore, protective tubing must be able to resist abrasions, stretching, and mechanical strain. The Fep heat shrink tube excels in these areas by forming a tough, protective shell that safeguards delicate components from external wear.

Whether wrapped around surgical scissors, laparoscopic tools, or fluid pathways, this tubing helps extend the lifespan of medical devices while maintaining strict hygiene standards.

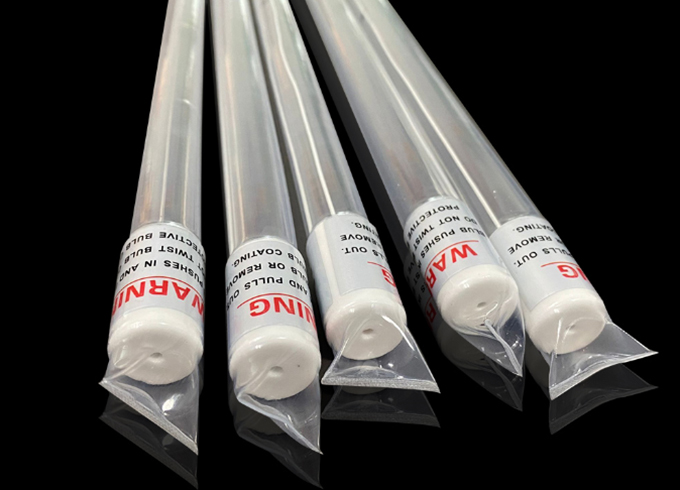

Medical FEP Heat shrink tube

Easy Installation and Customization

The installation process for Fep heat shrink tube is fast and straightforward. By applying controlled heat, the tubing contracts to tightly conform to the shape of the enclosed component. This creates a seamless, secure fit that not only protects but also seals out contaminants like bacteria, fungi, and mold.

In addition to its shrink-to-fit capability, this tubing can be custom-cut to any length and supplied in various diameters (from 1mm to 150mm) and wall thicknesses (0.1mm to 1mm). The available shrink ratios include 1.6:1 and 1.8:1, offering engineers design flexibility for tight or complex fits.

This high degree of customization enables medical equipment designers to specify the exact requirements for each use case.

Broad Chemical Resistance

Medical devices are often exposed to a range of fluids and chemicals, from cleaning agents to pharmaceutical compounds. FEP is highly resistant to chemical corrosion, allowing the Fep heat shrink tube to remain functional and safe even when in contact with aggressive substances.

It can resist a wide variety of chemicals, making it suitable for use in devices that handle diverse medical liquids and drugs. The tubing will not degrade, discolor, or lose its protective qualities under these conditions.

Performance in Extreme Environments

The operating temperature range of the Fep heat shrink tube is another reason for its popularity in critical medical environments. With thermal stability up to 200°C, it performs reliably in both hot and cold conditions without becoming brittle or losing its shape.

In addition, the tubing offers excellent flexibility and low-temperature impact resistance, meaning it remains easy to install and handle—even in refrigerated or cryogenic settings—without becoming brittle or cracking.

Typical Applications of FEP Heat Shrink Tubes in Medicine

Given its extensive list of properties, Fep heat shrink tube finds application across a wide range of medical disciplines:

-

Electrosurgical instruments: insulation and sealing

-

Laparoscopic tools: protective sheath for sterilizable use

-

Fluid management systems: clear and chemical-resistant tubing

-

Optical and fiber devices: transparent housing with electrical insulation

-

Implantable systems: biocompatible covering for safe integration

-

Catheters and endoscopes: visibility with sterilization compatibility

Its usage spans from operating rooms to laboratories, test benches to hospital wards, demonstrating the versatility and trust placed in this material.

Why FEP Heat Shrink Tubes Are Preferred in Healthcare

From a medical manufacturer’s standpoint, selecting Fep heat shrink tube means choosing performance, compliance, and reliability. It checks every box for quality, functionality, and regulatory adherence, especially for OEMs (Original Equipment Manufacturers) designing cutting-edge tools for clinical environments.

Moreover, the cost-benefit balance of FEP tubing makes it a worthwhile investment. Devices last longer, require less frequent replacement, and offer improved patient safety.

The Future of Medical Tubing Lies with FEP

In an industry where the smallest flaw can have serious consequences, choosing the right materials is critical. The Fep heat shrink tube continues to prove itself as a superior option for medical applications due to its unparalleled combination of features: high temperature resistance, transparency, electrical insulation, chemical stability, and biocompatibility.

With its ability to withstand up to 200°C, its optical clarity for visual inspection, resistance to harsh chemicals, and flexibility in cold environments, it delivers both performance and peace of mind. Add to that the options for custom cutting and versatile shrink ratios (1.6:1 and 1.8:1), and you have a tubing solution that adapts to a wide range of medical challenges.

As the medical field pushes for more advanced, minimally invasive, and multifunctional devices, the demand for high-performance materials like Fep heat shrink tube is only expected to grow. Manufacturers looking for tubing that meets regulatory standards while offering flexibility and reliability will find that FEP remains one of the most trusted materials in the market.

Frequently Asked Questions (FAQs) about FEP Heat Shrink Tube

Why are FEP heat shrink tubes relatively expensive?

FEP heat shrink tubes may appear costly at first. However, they are made from high – performance fluoropolymer materials with excellent chemical resistance, high – temperature stability, and electrical insulation properties. Their superior durability and reliability reduce the need for frequent replacements, making them more cost – effective in the long run. Additionally, purchasing in bulk can lead to significant cost savings.

Can FEP heat shrink tubes withstand high temperatures?

Yes. FEP heat shrink tubes can endure high temperatures up to 200°C (392°F). They maintain their structural integrity and functional properties even under continuous exposure to elevated temperatures, making them suitable for a wide range of high – temperature applications.

Are FEP heat shrink tubes environmentally friendly?

FEP materials are generally stable and do not release harmful substances during normal use. While they are not biodegradable in the traditional sense like some natural materials, they can be recycled through specialized processes.

Where can I buy FEP heat shrink tubes in bulk?

offers competitive wholesale prices for FEP heat shrink tubes. Buying in bulk from our website: www.insulation-tubing.com not only saves you money but also ensures a consistent supply for your projects. We provide a variety of sizes and specifications to meet different requirements.

Do FEP heat shrink tubes provide good electrical insulation?

Yes, FEP heat shrink tubes have outstanding electrical insulation properties. They have a high dielectric strength, low dielectric constant, and excellent volume resistivity, effectively preventing electrical leakage and ensuring reliable insulation for electrical and electronic components.

What are the main applications of FEP heat shrink tubes?

FEP heat shrink tubes are widely used in industries such as aerospace, electronics, telecommunications, and chemical processing. They are ideal for insulating wires and cables, protecting sensitive electronic components from environmental factors and mechanical damage, and providing chemical resistance in harsh industrial environments.

EP Heat Shrink tube

The Medical FEP Heat Shrink Tube is not merely a component—it’s an enabling technology. It empowers engineers to design safer, cleaner, and more effective medical tools that elevate patient care. Whether used in the latest robotic surgery system or a handheld diagnostic device, Fep heat shrink tube plays a silent yet crucial role in the evolution of modern medicine.For example: “Want to learn more about FEP Heat Shrink Tube purchasing information? Contact us now to get a quote!”