The Medical FEP Heat Shrink Tube is a vital enabler in modern healthcare, supporting safer, cleaner, and more efficient devices. From robotic surgery to diagnostics, FEP heat shrink tube plays a quiet but essential role in advancing patient care.

Sobre nosotros.

25 años de experiencia con nuestra potente tecnología, equipo de producción avanzado, instalaciones de prueba completas y un perfecto sistema de calidad ISO 13485.

Potente tecnología

Tenemos 25 años de experiencia en nuestra poderosa tecnología, equipos de producción avanzados, instalaciones de prueba completas y un sistema de calidad ISO completo.

Mejor servicio

«Adherirse a los principios de» brindar el mejor servicio a los clientes «y» expectativas del cliente orientadas a las personas «

Productos de alta calidad

Le proporcionaremos precios competitivos y productos de calidad.

Productos de alta calidad

Ofrecemos productos de alta calidad para que los clientes logren el éxito empresarial.

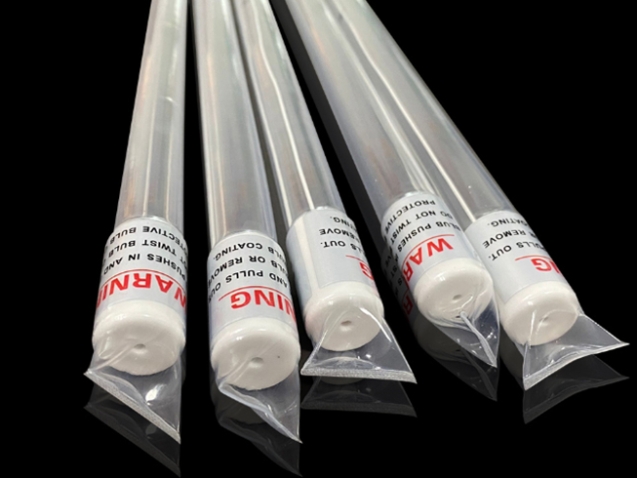

Tubo de protección de lámpara UV de tubo termocontraíble FEP

Información del producto:

Tubo termocontraíble FEP, la temperatura máxima de trabajo continuo es de 200 ℃ y la temperatura de contracción es de solo 110 ℃. Utilizado inicialmente en lámparas ultravioleta en matamoscas electrónicos y posteriormente utilizado en luz blanca, FEP ha demostrado ser el material de recubrimiento final para lámparas inastillables para esta aplicación. Cuando el vidrio y el mercurio están dañados, se pueden almacenar de manera segura en el vidrio y el mercurio, y no se degradará por el calor o los rayos ultravioleta de la lámpara.

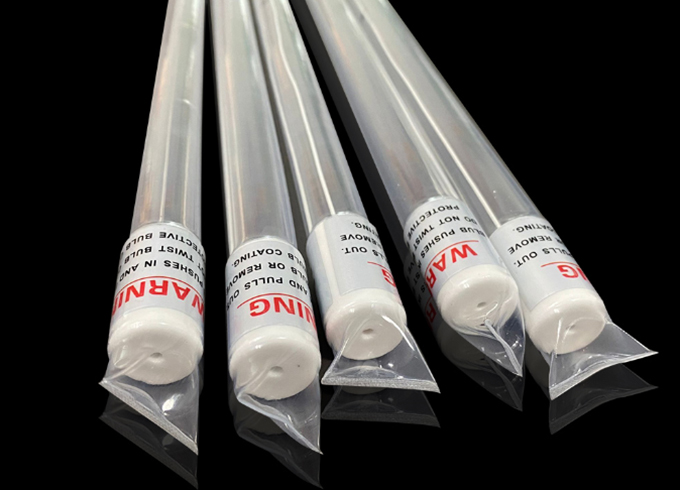

Tubo de silicona

Información del producto:

FORBEST ofrece una variedad de tubos de silicona hechos de este material multifuncional, incluidos los tubos de silicona vulcanizada de platino y los tubos de silicona vulcanizada oxidada, para garantizar la menor cantidad de extraíbles posible. Nuestra sala blanca de última generación está especialmente diseñada para fabricar productos especialmente adecuados para aplicaciones médicas. Además, nuestro tubo de silicona de grado industrial proporciona un rendimiento excelente a un costo relativamente bajo.

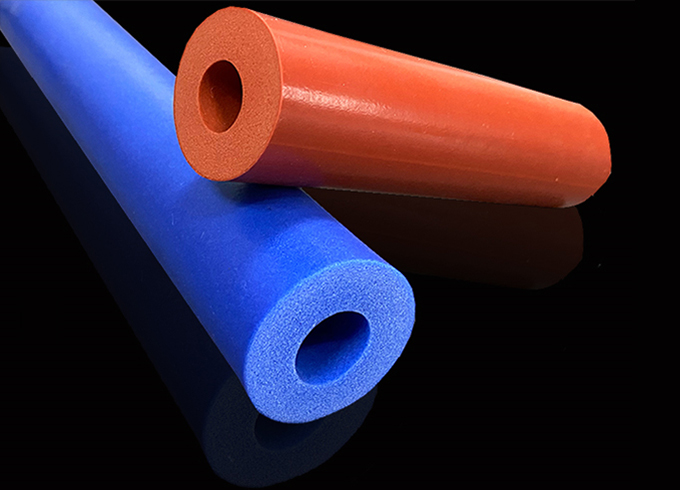

Tubo de espuma de silicona hueco aislado cerrado

Información del producto:

2. rango de temperatura: -40 ~ + 250 ° c

3. Densidad: 0,3 ~ 0,6 g / cm3

4. Dureza: 7-20Shore C

5. Resistencia a la tracción: 10 psi

6.Longitud: cualquier longitud

7.Color: cualquier color disponible

8.Áreas de aplicación

9.Los tubos de espuma de caucho de silicona se utilizan ampliamente en la industria de panadería, fabricación de maquinaria, industria electrónica, industria de equipos de fusión en caliente, para sellar, aislar y juntas y sellos de alto rendimiento.

últimas noticias

Asesino de moscas de mosquitos

Equipo medico

Laboratorio

Bomba peristáltica

Electrodomésticos

Horno

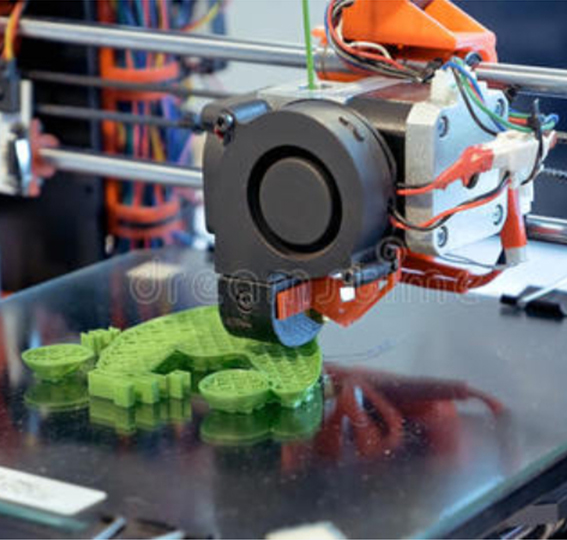

Impresión 3d

Aptitud

Últimas noticias.

fep heat shrink tubing manufacturer

Forbest FEP Heat Shrink Tubing: Key Material for High-Performance Medical Equipment In the fiel ...

What is the difference between PTFE, FEP, PFA, and ETFE?

Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Tefl The non-stick coa ...

Forbest Manufacturing Co., Ltd

Fundada en 1995, FORBEST es un fabricante profesional de tubos de plástico, tubos de goma, tubos de espuma y más productos relacionados.

Contacto

- Número:+86-755-21011145

- Email :[email protected]

- Dirección:Fulian Industrial Longhua Town Shenzhen City GuangDong Province China