The Medical FEP Heat Shrink Tube is a vital enabler in modern healthcare, supporting safer, cleaner, and more efficient devices. From robotic surgery to diagnostics, FEP heat shrink tube plays a quiet but essential role in advancing patient care.

우리 에 대해 서

우리는 강력한 기술, 첨단 생산 장비, 완벽한 테스트 시설 및 완벽한 ISO 13485 품질 시스템에 대한 25년의 경험을 보유하고 있습니다.

강력한 기술

우리는 강력한 기술, 고급 생산 장비, 완벽한 테스트 시설 및 완벽한 ISO 품질 시스템에서 25 년의 경험을 보유하고 있습니다.

최고의 서비스

“”고객에게 최상의 서비스 제공 “및”사람 중심의 고객 기대 “원칙을 준수합니다.

고품질 제품

경쟁력있는 가격과 고품질의 제품을 제공하겠습니다.

고품질 제품

고객이 비즈니스 성공을 달성 할 수 있도록 고품질 제품을 제공합니다.

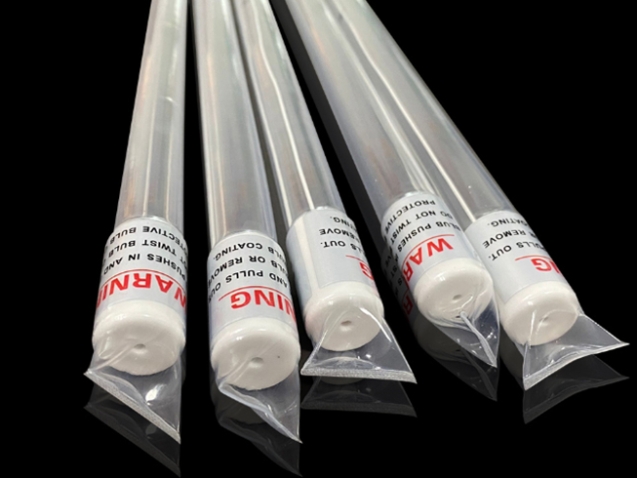

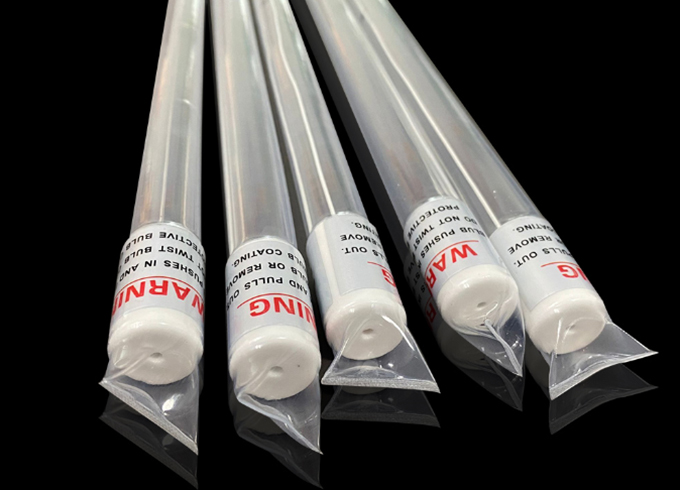

FEP 열 수축 튜브 UV 램프 커버

제품 정보:

FEP 열 수축 관, 최대 연속 작 동 온도 200 ℃, 수축 온 도 는 110 ℃ 에 불과 합 니 다. 최초 로 전자 파리 퇴치 기 에 사 용 된 자외선 램프 는 백색 광 에 대하 여 FEP 는 본 응용 프로그램의 깨 진 불 을 막 는 최종 코팅 재료 임 을 증명 하 였 습 니 다.유리 와 수은 이 파손 되 었 을 때 는 안전하게 제어 되 지만 불 에서 나 오 는 열량 이나 자외선 에 의 해 퇴화 되 지 는 않 는 다.

실리콘 튜브

제품 정보:

FORBEST는 백금 가황 실리콘 튜브 및 산화 가황 실리콘 튜브를 포함하여이 다기능 소재로 만든 다양한 실리콘 튜브를 제공하여 가능한 한 적은 양의 추출물을 보장합니다. 당사의 최첨단 클린 룸은 특히 의료 분야에 적합한 제품을 제조하도록 특별히 설계되었습니다. 또한 산업용 등급의 실리콘 튜브는 비교적 저렴한 비용으로 우수한 성능을 제공합니다.

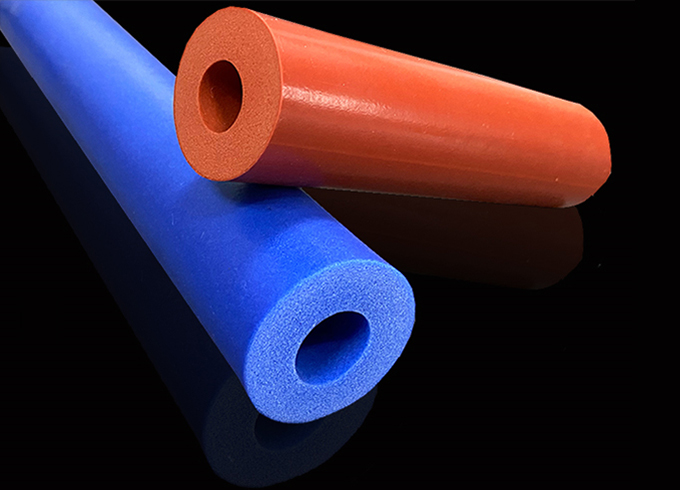

폐쇄 절연 중공 실리콘 폼 튜브

제품 정보:

1. ROHS SGS 표준 및 FDA 등급 준수

2.온도 편차 : -40 ~ + 250 ° c

3.신장: 250 %

4.밀도: 0.3 ~ 0.6g / cm3

5.경도: 7-20Shore C

6.인장 강도 : 10psi

7.길이 : 모든 길이

8.색상 : 사용 가능한 색상

9.적용 분야:실리콘 고무 폼 튜브는 제빵 산업, 기계 제조, 전자 산업, 핫멜트 장비 산업, 밀봉, 절연 및 고성능 개스킷 및 씰에 널리 사용됩니다.

최신 소식

fep heat shrink tubing manufacturer

Forbest FEP Heat Shrink Tubing: Key Material for High-Performance Medical Equipment In the fiel ...

What is the difference between PTFE, FEP, PFA, and ETFE?

Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Teflon PTFE: Tefl The non-stick coa ...