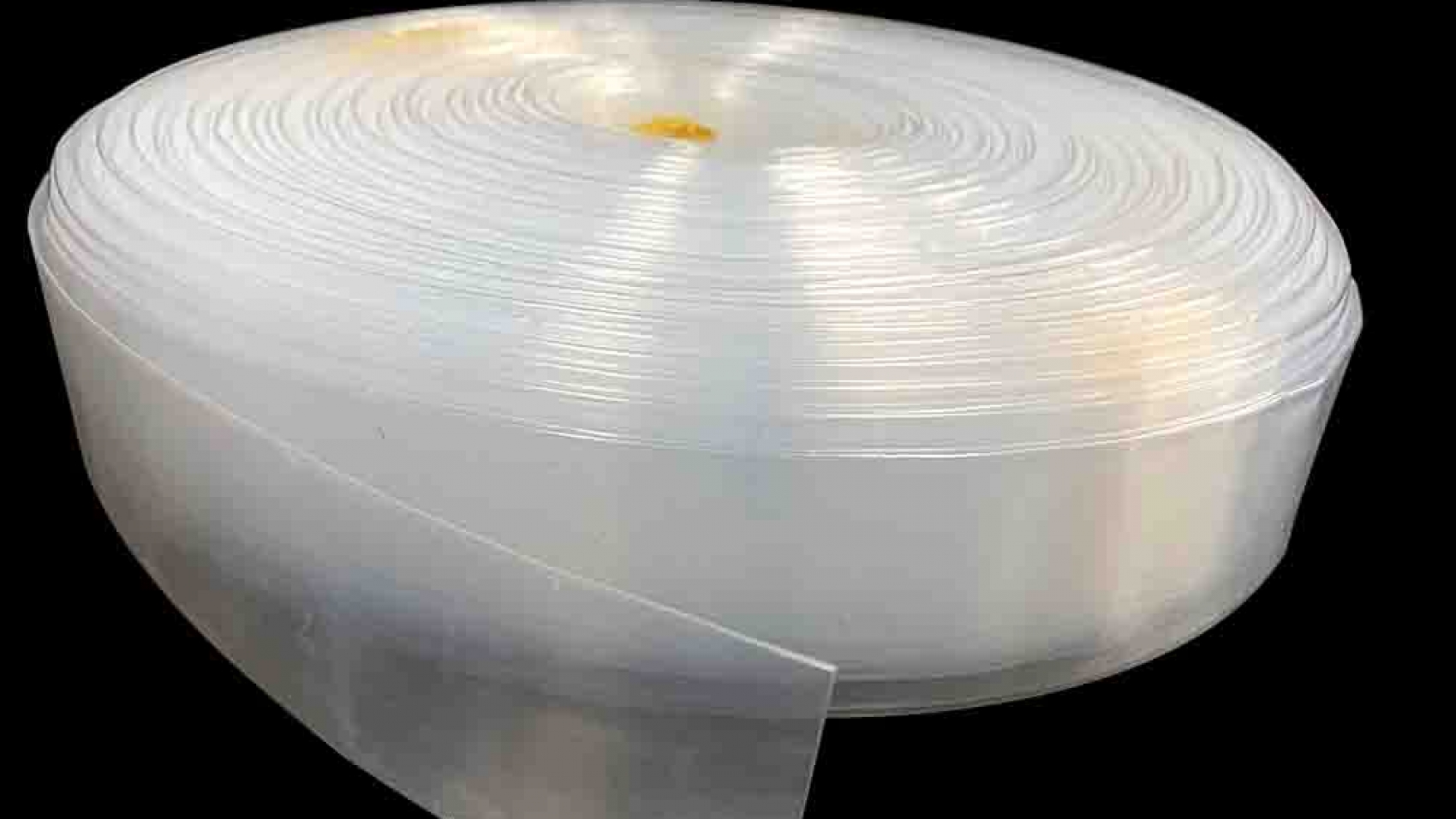

Forbest Manufacturing Co.LTD are FEP heat shrink tubing manufactuer

Our FEP heat shrink tubing is extruded and expanded with high quality Fep(F46)/Pfa. It has excellent electrical insulation, high flame retardant and self-lubricating properties, resistance to ultra-high temperature and chemical agents, and resistance to almost all oils and chemicals. Widely used in automotive, military, aerospace, electronic chemical and other fields.

【Features】

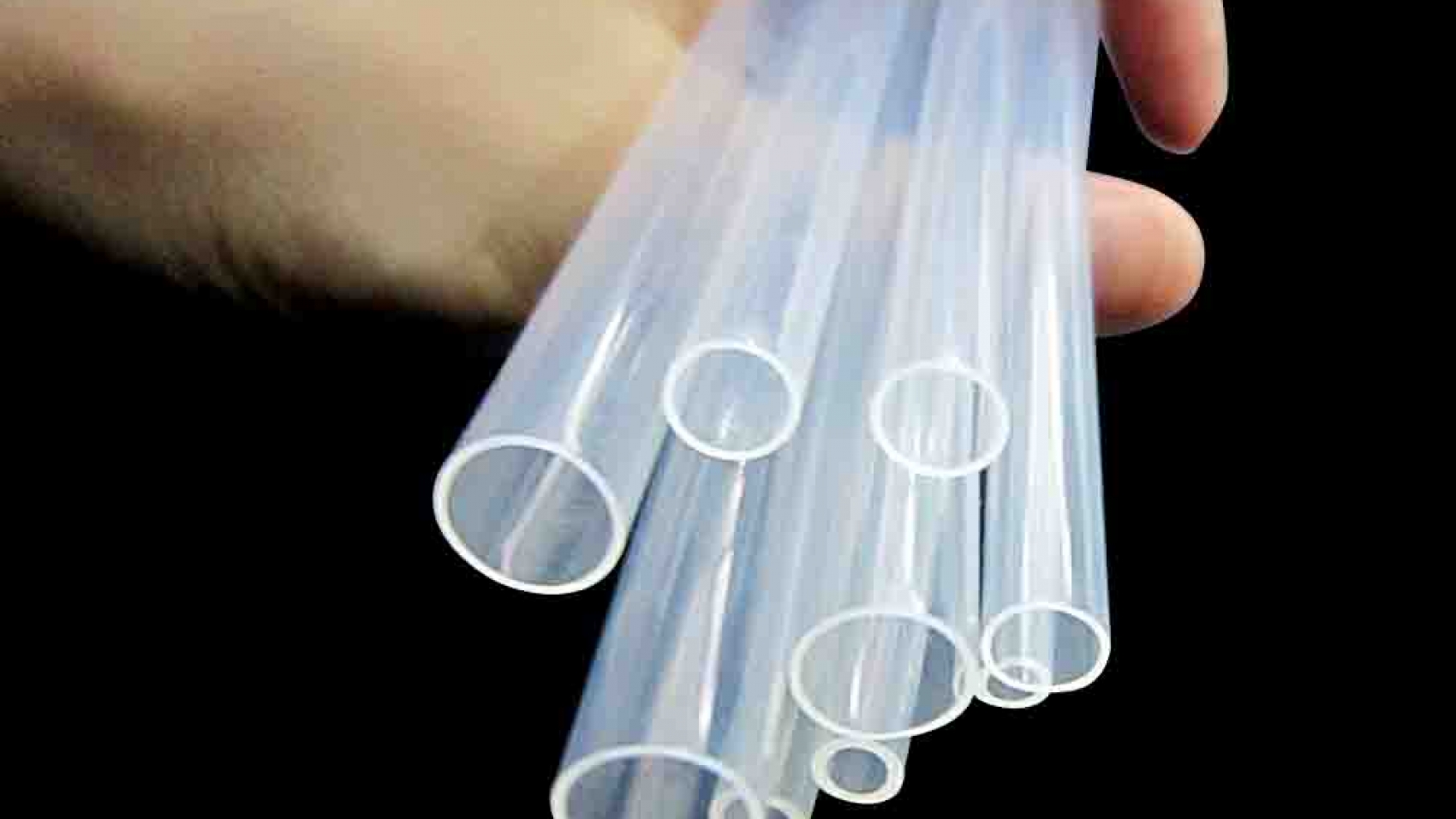

Corrosion resistance, strong acid, alkali, chemical reagent, oil resistance

Fep (F46) operating temperature: -65℃~200℃; shrinkage temperature: ≥110℃

Pfa (F46) operating temperature: -65℃~260℃; shrinkage temperature: ≥150℃

Environmental Standard: RoHS

Standard Color: Transparent,